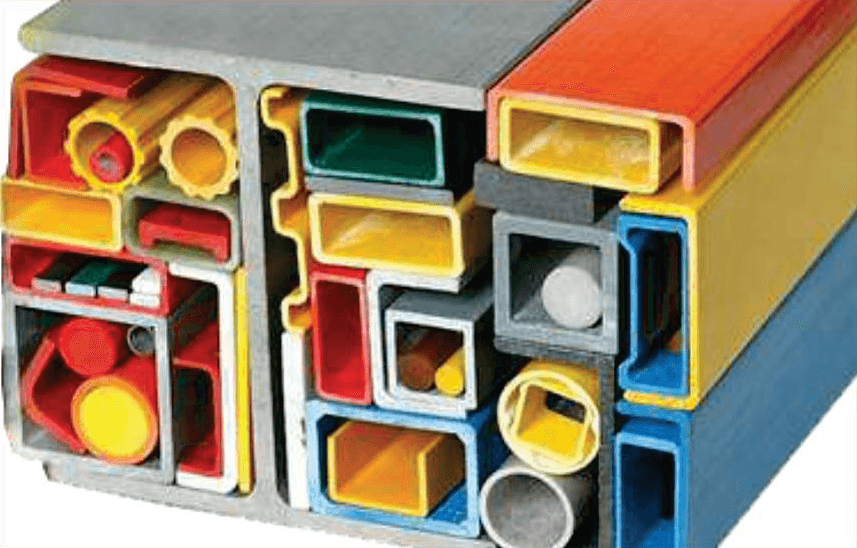

FRP Pultruded products are revolutionary replacement for traditional materials

like Steel, Wood, Aluminium & etc.

Traditional materials deteriorate and maintenance cost is quite high while in use for a longer period like Wooden item gets destroyed due to fungal attacks, Steel gets rusted, Aluminium gets deformed due to lower strength.

So what’s the solution?

Now, think of sections that won’t get rusted, have lesser maintenance cost and lightweight, Fiber glass pultruded sections/profile is the solution.

Pultruded fiber glass sections/profiles are equally strong as Steel having lower weight and it is far better option against corrosion, fungal/insect attack, deformation & is non-conductive of electricity with lots of other benefits. FRP profiles can be made as per required shape/design for specific application and meet required usage parameters by giving additionally better life for years. In brief, Fiberglass Pultruded items give a long term benefits with respect to cost and enhance performance as well. It is advisable and worth to work with FRP Pultruded parts in mind while considering the long term benefits.

Advantages:

Lighter weight: FRP Pultruded Products are having less weight by 25-30% of Steel and 65-70% of Aluminum weight. So, these can be transported, handled and lifted at site very easily. Complete Set up can be Pre-installed & dispatched to site as CKD condition for easy reassembly by using simple tools.

Equivalent Strength: FRP has equivalent strength that of Steel structural and better than aluminium. It is widely used for building structures, walkways, office /storage floors, hand rails & other platforms.

Anti-Corrosive: Pultruded components/Sections do not get damaged during use in corrosive environment. So it is an obvious option for inside or outside locations having wide application in industries like Chemical plants, Paper mills & other water treatment plants including coastal locations.

Non-Conductive: Fiber reinforced Pultruded sections are electrically non-conductive and thermally very low conductive.

Dimensional Permanency: The coefficient of thermal expansion of Pultruded products is slightly less than Steel and significantly less than Aluminum.

Electro-Magnetic waves Compatibility: FRP Pultruded products do not hinder the functionality of electromagnetic equipment and are friendly to radio waves & microwaves as well.

Assembly of Parts: Pultruded Products can be fabricated into a solo part by reducing the number of items and joiners requirement.

Visual Demand: FRP Pultruded profiles can be pigmented during manufacturing process, throughout the part thickness as per requirement to match the site condition with variety of other textures as well.