Upto 1500 TR With FRP Basin in single cell

Product Description:

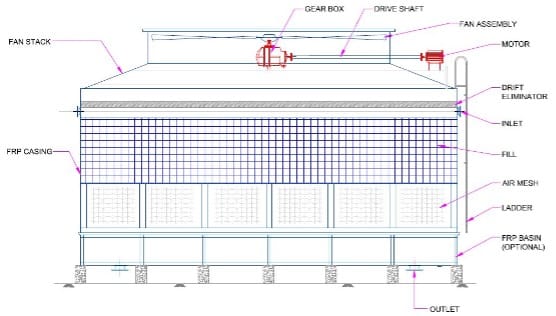

Casing: The casing of Paltech cooling towers is constructed using FRP molded panels. All joints are sealed with a waterproof compound and fastened together with galvanized steel bolts or stainless steel bolts if specified. Additional embossing enhances the casing’s strength for durability.

Fill: The cooling towers are equipped with Honeycomb/Film Fills and Splash Type PVC/PP Fills, ensuring an extended contact area and higher heat transfer efficiency.

Fan: Paltech utilizes cast Aluminum alloy/S.S./FRP fans designed aerodynamically in an axial flow type, ensuring high efficiency in cooling operations.

Drift Eliminator: Specially designed multi-blade rotary drift eliminators, made of FRP/Aluminum sheets, reduce carryout losses by preventing the entrainment of moisture ropes in the air stream.

Motor: The cooling towers are powered by special low RPM totally enclosed motors of vertical, flange type with an enlarged and threaded shaft. These motors are sealed and weatherproofed to IP-55 protection standards. For larger capacities, a gear reducer-driven system is provided.

Water Distribution System: Hot water is raised by a hot water riser and transported inside through an M.S.H.D.G./P.V.C. hot water header. Branch distribution pipes, equipped with Polypropylene Splash cups/non-clogging nozzles, are connected to the hot water header, ensuring uniform water distribution over the entire fill. This system is maintenance-free.

Capacity: The cooling towers are available in capacities ranging from 3TR to 1500TR in a single cell. Larger capacities are available through multiple cell construction, providing flexibility for various cooling requirements.

Note: Dimensions & other Engineering Data are available with Proposal / Quotation.